On the basis of years of 3D printing 1.0 equipment and applications, we have independently mastered 3DP and BJ line scanning high-speed 3D printing 2.0 equipment, materials and processes, which can meet the manufacturing needs of products of different sizes (from millimeter to meter), and independently researched and developed a series of intelligent equipment, such as SLS selective laser sintering, SLM selective laser melting, 3DP sand printing, BJ binder jet metal/ceramic printing and so on.

The company also has laser and binder jet 3D printing equipment and materials technology and application process, business covers 3D printing equipment, raw materials research and development and production, rapid manufacturing services for finished metal parts, 3D printing process technology support services, etc., and has established a complete 3D printing rapid manufacturing industry chain, which is widely used in the aerospace, ship pump valves, automotive, energy power, industrial machinery, rail transportation, 3C electronics, education and scientific research, sculpture and cultural creation, rehabilitation and medical treatment and other industries.

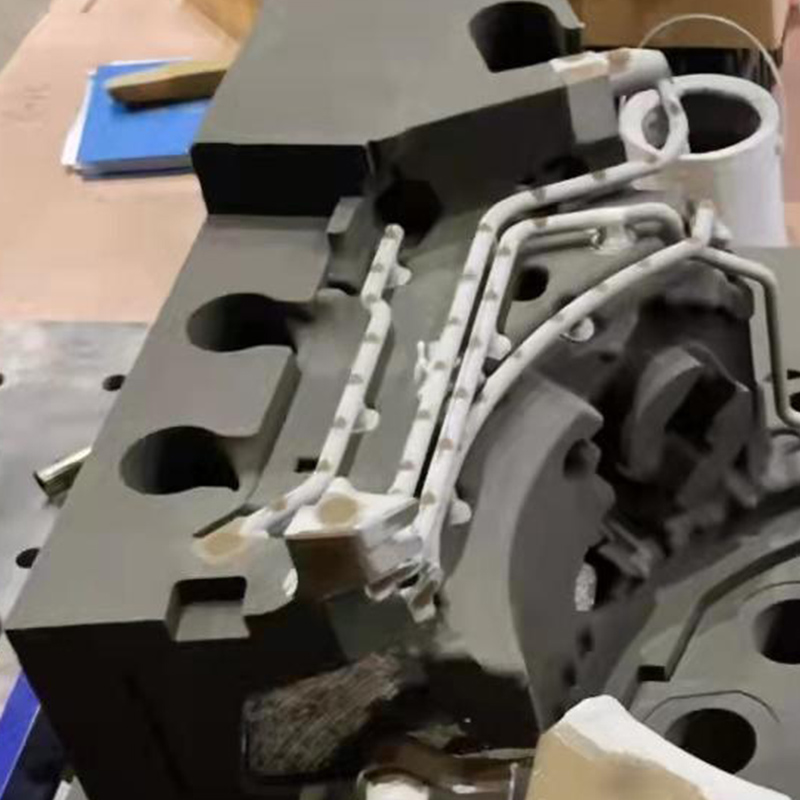

Difficulty:

A single process can not meet the complex oil circuit sand print, easy to deform before casting back to the temperature process, insufficient strength (1.5-2.5MPa), casting is easy to cause punch off.

Solution:

The "SLS coated sand molding process + 3DP resin sand molding process" combination of sand mold manufacturing has realized the integration of high-precision and high-strength casting molding of complex structural parts of power components (large, thin-walled, small pipelines, etc.); this process has been selected as a typical application scenario of additive manufacturing by the Ministry of Industry and Information Technology.

Difficulty:

Large, thin-walled, with complex spiral cooling channels between the inner and outer walls, and channel widths that needed to be verified repeatedly. Short-term, rapid delivery was required to validate the design structure and allow for timely changes to the model data;

Traditional casting process, product qualification rate is low, high cost, long cycle.

Solution:

The 3DP sand casting process enables rapid delivery of this product by means of a closed mold.

3D Printing Technology, Inc. is a 3D printing equipment and rapid manufacturing service provider, a national "specialization, specialization and innovation" small giant enterprise, the Ministry of Industry and Information Technology additive manufacturing typical application scenarios supplier. At the same time has laser and binder jet 3D printing equipment and materials technology and application process, business covers 3D printing equipment, raw materials research and development and production, metal parts rapid manufacturing services, 3D printing process technology support services, etc., to establish a complete 3D printing additive manufacturing industry chain, widely used in aerospace, ship pumps and valves, automotive, energy power, industrial machinery, rail transportation, 3C, electronics, education and research, sculpture, culture and creativity. electronics, education and scientific research, sculpture and cultural creation, rehabilitation and medical industries.View Details>>

Address:No.7 Jin Yi Street, Shunyi District, Beijing, China

Tel:

E-mail: [email protected]

Links:,,,,,