Beijing SANDI Technology Co.(3D Printing Technology, Inc.) is a 3D printing equipment and rapid manufacturing service provider, a national specialized, special and new "small giant" enterprise, and a typical application scenario supplier of additive manufacturing of the Ministry of Industry and Information Technology. At the same time has laser and binder jet 3D printing equipment and materials technology and application process, three emperor technology business covers the development and production of 3D printing equipment, 3D printing raw materials development and production, 3D printing process technology support services, rapid finished parts manufacturing services, etc., to establish a complete 3D printing additive manufacturing industry chain, widely used in aerospace, electric power and energy, ships, pumps and valves, automobiles, rail transportation, industrial machinery, 3C additive manufacturing typical application scenarios, the Ministry of Industry and Information Technology, and the company is a leading supplier of additive manufacturing, rail transportation, industrial machinery, 3C electronics, rehabilitation and medical treatment, education and research, sculpture and cultural creation and other industries.

Since its Longyuan Molding successfully developed the first commercialized industrial-grade 3D printer with independent intellectual property rights in China in 1994, SANDY Technology has independently mastered 3DP and BJ line scanning high-speed 3D printing equipments, materials and processes on the basis of many years of 3D printing equipments and applications such as SLS, SLM, etc., to meet the manufacturing needs of products of different sizes (from millimeters to meters), and has independently researched and developed SLS sand/wax printing, SLM metal printing, 3DP sand printing, BJ binder jet metal/ceramic printing and other series of intelligent equipment; the depth of the development of the casting field for the casting of aluminum, cast copper, cast iron, cast magnesium, cast steel and other casting of nearly 30 kinds of material process formulas, and for stainless steel, mold steel, titanium alloy, SiC ceramics, such as the BJ molding powder material adaptability process formulas, as well as the 5 big Through the 3D casting factories and printing service centers in Xianyang, Shaanxi Province, Daiming, Hebei Province, Pingdingshan, Henan Province, Yulin, Guangxi Province, Rizhao, Shandong Province, Anyang, Anhui Province, and Tongling, etc., the company has established the capability of full-size, multi-material, and full-chain rapid manufacturing services, and it can provide users with the rapid trial production of finished metal parts and batch production, as well as the services of casting sand molds and wax molds printing.

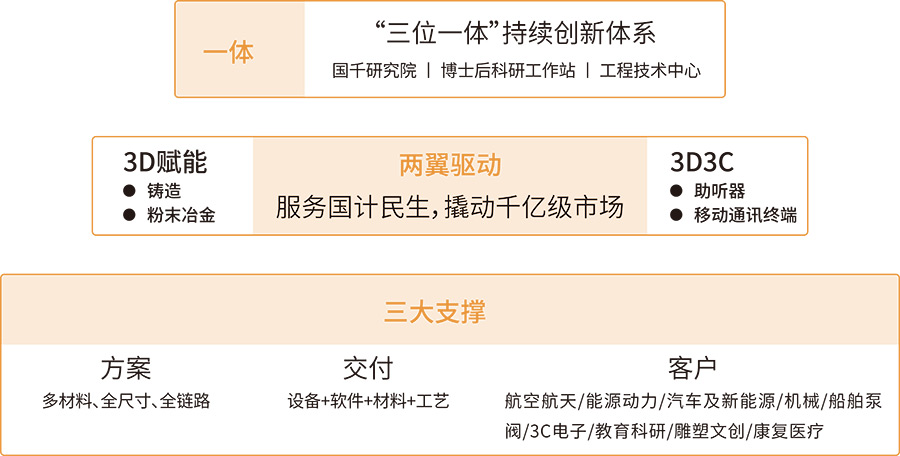

Based on the independent core technology of 3D printing equipment, materials and processes, SANDI Technology actively promotes the industrialized scale application of 3D printing and empowers manufacturing with digital technology.3D Empowerment): Through self-built and M&A foundries, to open up the "3D printing + casting" process, the formation of a replicable demonstration model, to help traditional foundries transformation and upgrading, to achieve green, intelligent, high-end casting; binder jet 3D printing technology is applied to enhance the powder injection molding, to achieve rapid batch manufacturing without mold, to help the industry to improve quality and efficiency, to promote the quality development of traditional manufacturing, transformation and upgrading, and to stimulate the hundreds of billions of rapid manufacturing market. Increase efficiency, promote the traditional manufacturing high-quality development, transformation and upgrading, pulling hundreds of billions of rapid manufacturing market.

SANDY TECHNOLOGY actively promotes the application of 3D printing in the 3C field (3D3C), focuses on the development of 3C-specific 3D printing systems and material processes, making SLM and BJ technologies possible for automated large-scale 3D printing production.

SANDY TECHNOLOGY pioneers the use of 3D printing in rehabilitation medicine (3D MedicalThe company obtained China's first medical device registration certificate for 3D printed customized titanium alloy hearing aids, and established a sales channel for "Taiyin" system hearing aid products.

Relying on the "three-in-one" collaborative innovation system of Guoqian Science and Technology Research Institute, postdoctoral workstation and enterprise R&D team, SANDI and its enterprises have declared nearly 300 patents and copyrights, and passed the certification of ISO 9001 quality management system, ISO 13485 quality management system of medical devices, ISO 45001 We have passed ISO 9001 Quality Management System, ISO 13485 Medical Device Quality Management System, ISO 45001 Occupational Health and Safety Management System, ISO 14001 Environmental Management System, Green Supply Chain Management System, CE, EAC, etc., and have been granted the qualification of Class I and Class II medical device access. We have participated in the drafting of many national and industrial standards, and 3 national standards have been released. We have undertaken 6 key R&D projects of the Ministry of Science and Technology of the People's Republic of China as well as many key scientific and technological projects at provincial and municipal levels. Awarded the first batch of "Quality Supplier of Additive Manufacturing" by the Ministry of Industry and Information Technology (MIIT), "Supplier of Typical Application Scenarios of Additive Manufacturing" by the MIIT, "Gold Prize of China Hi-tech Achievement and New Product Trade Fair" by the MIIT. "Second Prize of Beijing Science and Technology Award, Second Prize of Guangxi Science and Technology Progress Award, Second Prize of China Nonferrous Metal Industry Science and Technology Award, Second Prize of Machinery Industry Science and Technology Award. Second Prize of China Nonferrous Metal Industry Science and Technology Award", "Second Prize of Machinery Industry Science and Technology Award", "Global Foundry Industry Innovative Technology and Products", "National Foundry Equipment Innovation Award" and other honors.

Relying on the "Trinity" continuous innovation system, the company is driven by the two wings of "3D Empowerment" and "3D3C", and realizes the sustainable and steady development of the company through the three major supports of "Solution + Delivery + Customer". + customer" three major support, to realize the company's sustained and steady development.

Xianyang 3D Casting Center covers an area of 22,000 square meters, with an existing building area of 18,000 square meters. It has more than 50 sets of advanced casting and processing equipment. Including 3DP sand printing equipment, SLS selective laser sintering 3D printing equipment and advanced modeling and testing equipment such as CMM, laser 3D scanner, vacuum direct reading spectrometer, etc., with an annual production capacity of about 1,800 tons of castings. Through sand casting, low-pressure casting, precision casting, metal-type casting and other professional casting processes, we provide small-lot rapid trial production of aluminum alloy, copper alloy, wear-resistant copper bushings, tin bronze, aluminum bronze, cast iron, cast steel and other castings.

Daiming 3D Smart Manufacturing Center covers an area of 70 acres, with a total construction area of 24,614 square meters. With independent intellectual property rights of 3D casting printing equipment, aluminum alloy casting production line, machining and testing equipment, with "process design + 3D printing + casting + machining and testing" integrated service capabilities, the establishment of 3D printing intelligent casting, liquid extrusion casting, low-pressure casting, differential pressure casting, gravity casting and other automation, Intelligent production line, can achieve an annual output of 20,000 tons of intelligent manufacturing of high-end aluminum alloy parts.

Henan Pingdingshan 3D Casting Center, covering an area of 180 acres, with a total construction area of 40,000 square meters, has independent intellectual property rights of 3D casting printing equipment, aluminum alloy casting production line, machining and testing equipment, painting, baking and environmental protection treatment equipment, the daily painting capacity of up to 200 square meters, the implementation of the national standard, enterprise standard standards and other standards. With the integrated service capability of "process design + 3D printing + casting + machining and testing", the company has set up automated and intelligent production lines for 3D printing intelligent casting, low-pressure casting, gravity casting, precision casting, etc., and possesses the research and development and manufacturing capability of super-large and shaped aluminum alloy castings, and can achieve an annual output of 5,000 tons of intelligently manufactured high-end aluminum alloy parts. Aluminum alloy parts with an annual output of 5,000 tons.

Yulin 3D Casting Center can provide 3DP sand printing rapid iron casting and aluminum casting services, based on the Guangdong-Hong Kong-Macao Greater Bay Area and the Beibu Gulf Economic Zone key corridor, radiating South China and ASEAN hundreds of billions of machinery manufacturing market, with an annual production capacity of 2 million pieces of high-performance aluminum alloy products.

Rizhao 3D Casting Center has SLM, SLS, 3DP, BJ and other 3D printers, lathes, boring machines, milling machines, CNC machining centers and other processing equipment, and a number of intelligent casting production line. Provide sand casting, precision casting and other rapid manufacturing services. Using laser SLM/SLS, inkjet BJ, light-curing SLA and other additive manufacturing technologies, combined with casting, CNC machining, surface treatment, heat treatment, non-destructive testing and other processes, to provide one-stop prototype prototype verification of aluminum alloys, copper alloys, stainless steel, cast iron and other one-stop sample, small and medium batch flexible manufacturing, manufacturing services for complex cavities and structures.

Tongling 3D Casting Center covers an area of 7,000 square meters, with domestic advanced level of investment casting, resin sand casting, gypsum casting, bronze forging and all kinds of metal art processing technology, with 3DP sand printing intelligent casting, liquid extrusion and low-pressure casting of high-performance aluminum alloys, copper alloys casting capacity.

Meet user needs and exceed service expectations;

Help employees grow and develop outstanding talent;

Respect for shareholders' rights and protection of investment interests;

Promote the development of the industry and return to the public;

Continuous development of enterprises, casting a hundred years of brand.

Address:No.7 Jin Yi Street, Shunyi District, Beijing, China

Tel:

E-mail: [email protected]

Links:,,,,,