For customers with casting business needs, when choosing a foundry to cooperate with, often focus on several key aspects, and as a subsidiary of Beijing SANDY Technology Co., Ltd, Hebei Daming Foundry (Daming County is located in the southeastern part of Handan City, Hebei Province, hereinafter referred to as Hebei Daming Foundry) has an outstanding performance in these aspects, and can effectively meet your needs.

Casting business often involves different levels of order requirements, customers are concerned about whether the foundry has the appropriate scale and capacity to undertake their projects. The Hebei Daming Foundry covers an area of 70 acres, with a total construction area of 24,614 square meters, which provides sufficient space for the layout of production facilities and lays the foundation for stable and efficient production. Especially important is that it can achieve an annual production capacity of 20,000 tons of high-end aluminum alloy parts for intelligent manufacturing, which means that no matter whether it is a small to medium-sized customized production or a large-scale batch order, Daimyo Foundry has the ability to complete the delivery on time and in accordance with the quality, so that you do not need to worry about the lack of production capacity to affect the progress of the business.

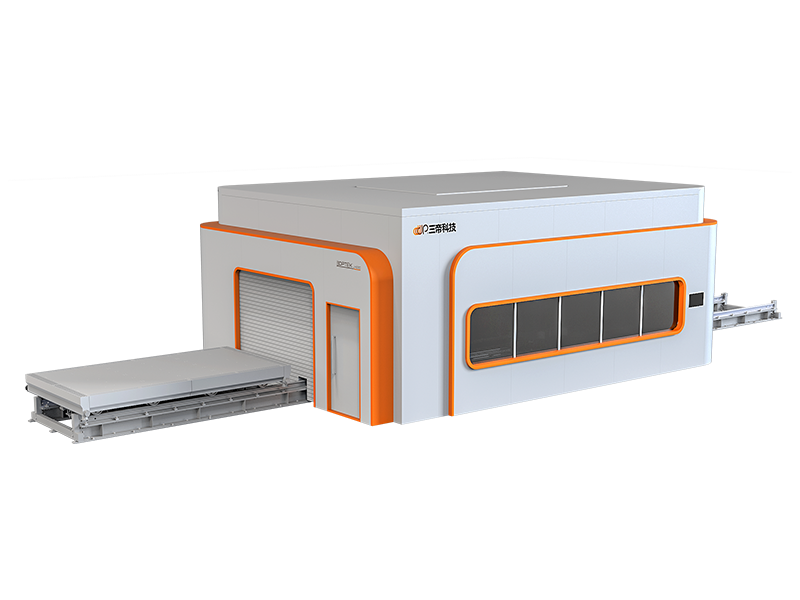

In the casting field, equipment and process directly determine the quality and manufacturability of products. The plant has independent intellectual property rights of casting 3D printing equipment, this advanced equipment in the manufacture of complex structural parts unique advantages, can accurately realize the design concept, for the manufacture of those parts that are difficult to complete the traditional process provides a possibility. Meanwhile, the aluminum alloy casting production line, perfect machining and testing equipment constitute a complete production chain. Moreover, the intelligent green 3D casting production line covers liquid squeeze casting, low-pressure casting, differential pressure casting, gravity casting and other processes, each of which is suitable for products with different characteristics, for example, liquid squeeze casting can improve the mechanical properties of castings, and low-pressure casting is suitable for the production of complex, thin-walled airtight parts, etc., so as to meet the manufacturing of products of multiple varieties and different performance requirements, and ensure that the various types of We can satisfy a wide variety of products with different performance requirements, ensuring that all kinds of metal parts you need can be produced here with high quality through the appropriate process.

Customers want to simplify the process as much as possible in the casting business cooperation, reduce communication costs, Daimyo Foundry has the "process design + 3D printing + casting + machining and testing" integrated service capabilities, which is just right to meet this demand. From the initial process design of the project, the professional team in the factory can carefully plan a scientific and reasonable manufacturing program based on your specific requirements for the product; then use 3D printing to quickly create samples or key components for verification; then casting to ensure the smooth implementation of mass production; machining to ensure the dimensional accuracy of the product; and finally testing to strictly control the quality, so that the entire casting business process can be efficiently and smoothly carried out within a factory. The whole casting business process can be completed efficiently and smoothly in one factory, avoiding the tediousness of repeatedly communicating and coordinating with multiple suppliers or different departments, saving your time and energy and making the casting project more efficient and orderly.

In short, Hebei Daimyo Foundry, with its solid production scale, advanced equipment and technology and perfect integration of service capabilities, has become an ideal partner for customers with casting business needs, and can help your business high-quality, sustainable development.

Address:No.7 Jin Yi Street, Shunyi District, Beijing, China

Tel:

E-mail: [email protected]

Links:,,,,,