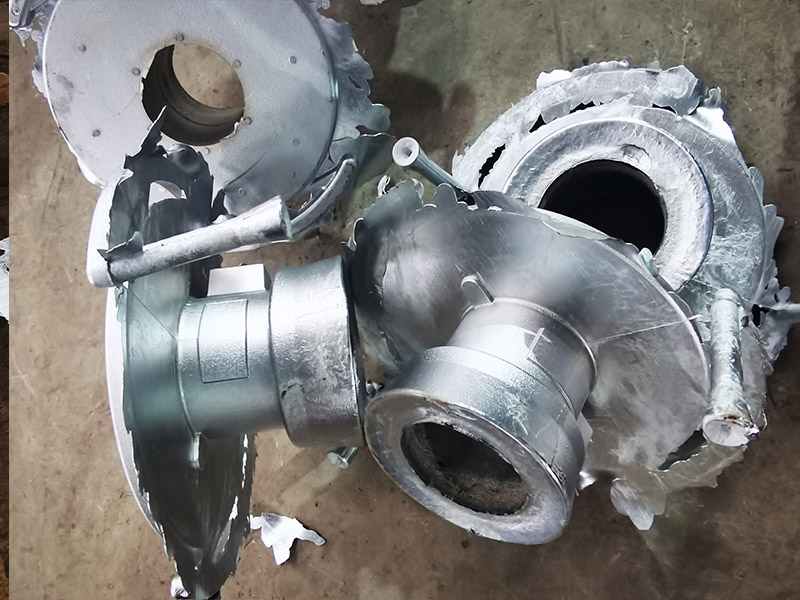

In the wave of change in manufacturing, 3D printing technology is gradually replacing traditional production methods, especially in the field of sand casting. Through 3D printing technology, not only can significantly improve production efficiency, but also realize the manufacture of complex parts. In this paper, we will discuss in depth how to use 3D printing technology to realize rapid sand casting.

Traditional sand casting often relies on hand-made molds, a process that is time-consuming, labor-intensive, and requires a high level of worker skill. In contrast, 3D printing sand casting generates sand molds directly from digital models, offering the following advantages:

Improvement of production efficiency: No need for mold making, direct printing of sand patterns, significantly reducing production time.

High design flexibility: It is possible to realize complex structures that are difficult to accomplish with conventional processes.

high precision: Digital manufacturing ensures product consistency and accuracy.

cost-effectiveness: Suitable for small batch production and customization needs with greater economy.

1. Digital model preparation

First, a 3D model of the part is designed using CAD software and optimized as follows:

Consider casting process requirements: Add an appropriate shrinkage margin.

Design of casting systems and risers: Ensures smooth flow of metallic fluids.

Perform mold filling and solidification simulation analysis: Predicting the quality and performance of castings.

Optimization of model structure: Ensure print viability.

2. Print device selection

There are two main technologies on the market for 3D printing sand molds:

Selective Laser Sintering (SLS): Suitable for precision parts.

Binder Jetting: Suitable for large castings. To be considered when selecting equipment:

Print Size: Select the right equipment for the part size.

Printing Accuracy: Ensure that design requirements are met.

production efficiency: Selected according to production requirements.

Material compatibility: Ensure that the device supports the required print material.

3. Material preparation

Sand printing materials mainly include:

Special casting sand: Uniform particle size and good fluidity.

Bonding agent: Ensure sand strength.

catalyzer: Accelerates the curing process. The choice of material directly affects the quality of the casting and needs to be optimized in proportion to the specific application scenario.

4. Print process control

The following key points need to be noted during the printing process:

Print room temperature and humidity control: Ensure that the printing environment is stable.

Uniformity of sand spreading: Ensures the densification of the sand mold.

Adjustment of binder dosage: Ensure sand strength.

Curing time control: Avoid over- or under-curing.

5. Post-treatment processes

Printing the finished sand pattern needs to be done:

Clearing loose sand: Ensure a smooth surface.

Strength test: Ensure that the sand mold can withstand the casting pressure.

Dimensional Inspection: Ensure compliance with design specifications.

surface treatment: Improve the surface quality of castings.

To ensure the quality of the castings, focus is required:

1. Sand quality control

Compaction test: Ensure that the sand is dense.

Compressive strength test: Ensure that the sand mold can withstand the casting pressure.

Breathability check: To avoid porosity in castings.

Verification of dimensional accuracy: Ensure compliance with design requirements.

2. Casting process control

Pouring temperature monitoring: Ensures metallic liquid flow.

Pouring speed control: Avoid impact of metallic liquids on the sand mold.

Control of cooling conditions: Ensure uniform cooling of the casting.

Timing judgment of demolding: Avoid deformation of castings.

Sand cracking

rationale: Improperly proportioned or inadequately cured binder.

tackle: Adjust ratios to optimize curing parameters.

Dimensional deviations

rationale: Improperly set print parameters or material shrinkage.

tackle: Optimize print parameters to compensate for shrinkage.

Poor surface quality

rationale: Inappropriate sand grain size or uneven sand spreading.

tackle: Selection of suitable grit and improvement of the sand laying process.

3D printing sand casting technology is rapidly evolving and will play an important role in the future in the following areas:

Aerospace parts manufacturing: Meets the needs of high precision and complex structures.

Development of prototype parts for the automotive industry: Shorten the R&D cycle.

Production of key components for construction machinery: Increase productivity.

Art casting and other personalization: Realization of complex designs.

3D printing sand casting technology is a product of the deep integration of traditional manufacturing and modern digital technology, which not only improves production efficiency, but also provides new possibilities for product innovation. With the continuous progress of technology, this process will be widely used in more fields. Enterprises in the use of this technology, you need to fully consider their own needs, choose the right equipment and process parameters, and in practice, continuous optimization and improvement, in order to give full play to its advantages.

The principle of sand 3D printing is a manufacturing method that transforms a three-dimensional digital model into a solid sand pattern. Specifically, it utilizes 3D printing equipment to build up layers of sand powder, which are bonded together with a specific binder or curing agent to form a sand mold with a complex internal structure. The sand mold is then dried or cured to make it strong enough to handle the subsequent casting process.

The advantage of this technology is that it meets the need for fast, customized and small production runs, bringing greater efficiency and quality to the casting process.

Address:No.7 Jin Yi Street, Shunyi District, Beijing, China

Tel:

E-mail: [email protected]

Links:,,,,,