3D printing technology has been developed for more than thirty years, and its industrialization application global compound annual growth rate in 20% above, China even higher, but due to its relatively small output value base, 3D printing industry, despite its significance, so far it is still a small industry. 3D printing industrialization is slow mainly due to two reasons: one is the low efficiency of the printing, that is, the manufacturing speed is slow; the second is that the printing material is expensive, that is, the Manufacturing cost is high. A slow and expensive technology is difficult to be applied to the production line, which is why most of the main users of 3D printing equipment are research institutes, R&D departments of large companies, schools and 3D printing service organizations.

In order to solve the problem of traditional 3D printing is both slow and expensive, 3D printing 2.0 Binder Jetting (Binder Jetting/3DP, hereinafter referred to as BJ) process has emerged. Compared to 3D printing 1.0, such as PBF, DED and other metal additive manufacturing process is the use of "point scanning" technology, the existence of processing efficiency is low, the cost is several times that of the traditional manufacturing technology, it is difficult to realize the large-scale industrialization of the application of the "line scanning" technology, the 3D printing 2.0 Binder Jetting (BJ) process has emerged. 3D printing 2.0 binder jetting BJ process using "line scanning" technology is a high-efficiency, high-precision additive manufacturing technology, which follows the traditional powder metallurgy industry's material system and sintering process, low cost, high degree of standardization of materials, can provide high-efficiency, high-quality, low-cost metal additive manufacturing solutions for the industrial session can be applied to the production line, for the large-scale application of 3D printing technology to lay a solid foundation. solid foundation. It is expected that 3D printing 2.0 will bring breakthrough and continuous growth for the 3D printing industry.

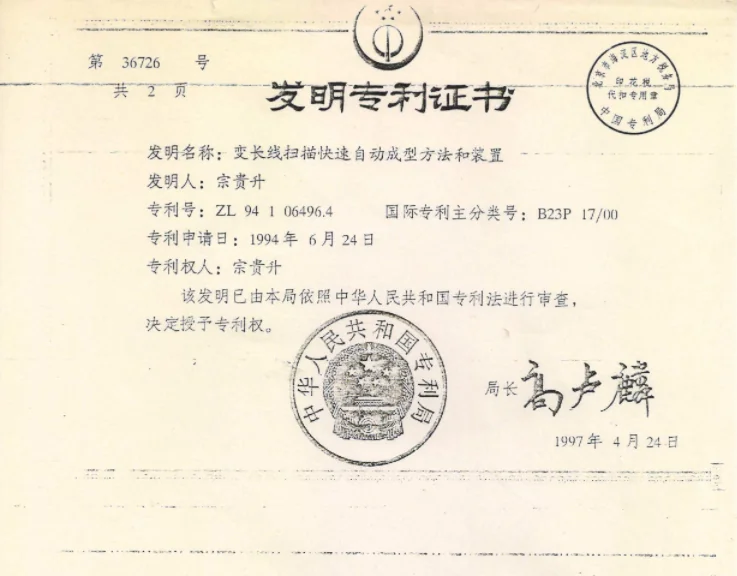

Internationally, Desktop Metal, HP, Digital Metal, GE and other global technology companies are optimistic about the market potential of BJ metal technology, in the past five years have completed the development of BJ metal technology, and achieved a certain degree of industrialization applications. As a large manufacturing country, China's market demand for BJ metal technology is even more urgent, especially from the MIM (Metal Injection Molding) industry for rapid prototyping and small and medium-sized mass production. Against this background, domestic BJ metal technology has developed rapidly in recent years. In fact, as early as 1994, Dr. Zong Guisheng, the founder of Beijing Longyuan Automatic Forming System Co., Ltd (a subsidiary of SANDI Technology, hereinafter referred to as "Longyuan Forming"), put forward the concept of "line scanning" and declared "Since 2018, through the technological innovation of the postdoctoral team at the postdoctoral workstation and the engineering innovation of the R&D team, Longyuan has successfully developed and produced a series of BJ equipment and 5 series of adhesives applicable to more than 20 materials. of 5 series of bonding agents, and put them on the market.

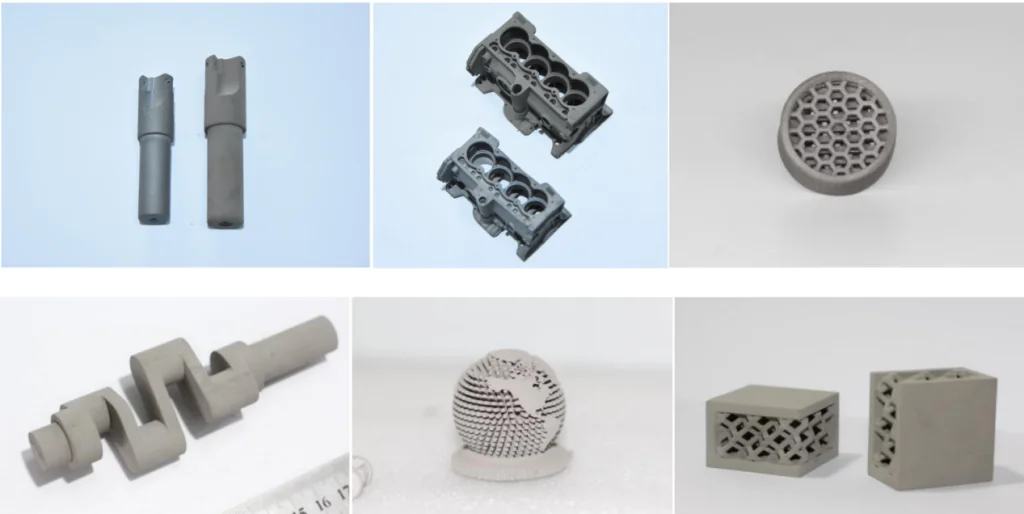

Based on the synergistic innovation system of the company's Guoqian Science and Technology Research Institute, post-doctoral workstation and product development team, and the foundation of nearly 30 years of development of additive manufacturing equipment, Longyuan Molding has independently mastered a number of key technologies related to the equipment, materials and processes of the binder injection molding technology, and has completed the development of R&D R-series and production P-series series of equipments and the development of systematic material processes, such as iron-based materials, non-ferrous metals, high temperature alloys, refractory metals, ceramic materials, inorganic salts, polymer materials and food materials. Alloys, refractory metals, ceramic materials, inorganic salts, polymer materials, food materials and other systematic material technology development.

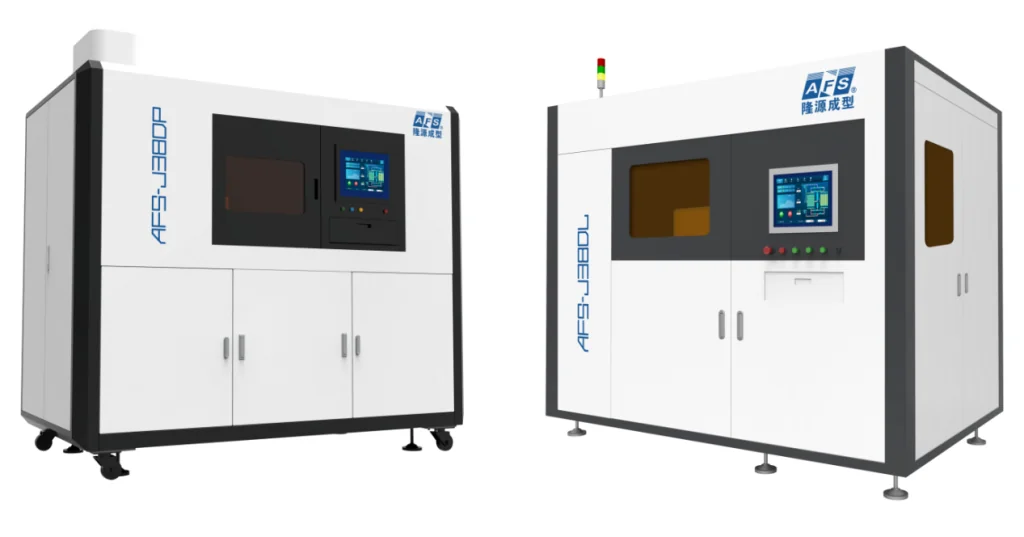

Longyuan Molding R series equipment AFS-J120R and AFS-J380R are R&D type equipment for universities, research institutes, enterprise R&D organizations and so on. This series of equipment can realize the highest ±0.2mm printing accuracy, 400~800DPI resolution, 2.5L/h printing speed and 55~62% green blank density. The equipment is easy and quick to operate, with flexible replacement of powder material and binder ink, concise structure, easy maintenance, and effective guarantee of scientific research efficiency and experimental reproducibility. Adopting self-developed industrial control software and data processing software, the process parameters are highly open and independently adjustable, which is not only compatible with a wide range of materials, but also more suitable for exploratory research and rapid preparation of new materials iteration.

P series equipment is production-oriented equipment for MIM, mold, tooling and other industries. This series of equipment adopts the latest top-feeding single-cylinder structure, equipped with V+ precise powder drop system, double-roller composite high-density powder spreading system, automatic nozzle cleaning, built-in air purification system and other devices, easy and quick to operate, flexible replacement of powder materials and binder ink, and effective protection of production efficiency. It can realize printing accuracy of ±0.15mm, resolution of 400~1200DPI (freely adjustable), printing speed of up to 2.5L/h and green blank density of 55~62%. High-end production equipment AFS-J380L is also equipped with a high-precision molding cylinder transfer vehicle, molding cylinder can be quickly transferred and quickly replaced, saving curing waiting time; the highest printing accuracy of up to ± 0.1mm, the highest printing speed of up to 3.6L / h, the relevant technical indicators up to the international advanced level.

In addition, Longyuan Forming has the ability to design binder formulations independently, which can meet the development needs of customers for customized binders for new materials and applications. On the basis of the equipment, it has successfully developed a series of BJ-specific binder formulations, which are applicable to more than 20 kinds of matrix materials, such as iron-based alloys, light metal alloys, organic glass, ceramics and so on. Among them, the degreasing and sintering process of SS316L, SS420, 18Ni300 and many other materials meet the international material standards of MIM industry. In addition, the company has set up professional technical service centers across the country, which can respond quickly to customer needs at all times and provide solid guarantee for the stable operation of the equipment.

BJ metal technology is known as "Additive 2.0" technology because of its high printing efficiency, low material cost, cost-effective equipment, no additional support, suitable for batch, etc. It will be used in automotive, hardware, electronics, tools, molds, cutting tools, medical equipment, sports equipment and other industries to form a large-scale industrial applications, with a vast market space. Has a broad market space, the future market size of more than 100 billion yuan. At the same time, as a direct metal molding technology, the development and application of BJ metal technology is also gradually growing into the core technology trends in the field of metal additive manufacturing, in the production of batch metal parts show a strong vitality. It is believed that, in the future, this technology will profoundly affect the traditional manufacturing industry, and will change the market pattern of the metal additive manufacturing industry.

Address:No.7 Jin Yi Street, Shunyi District, Beijing, China

Tel:

E-mail: [email protected]

Links:,,,,,